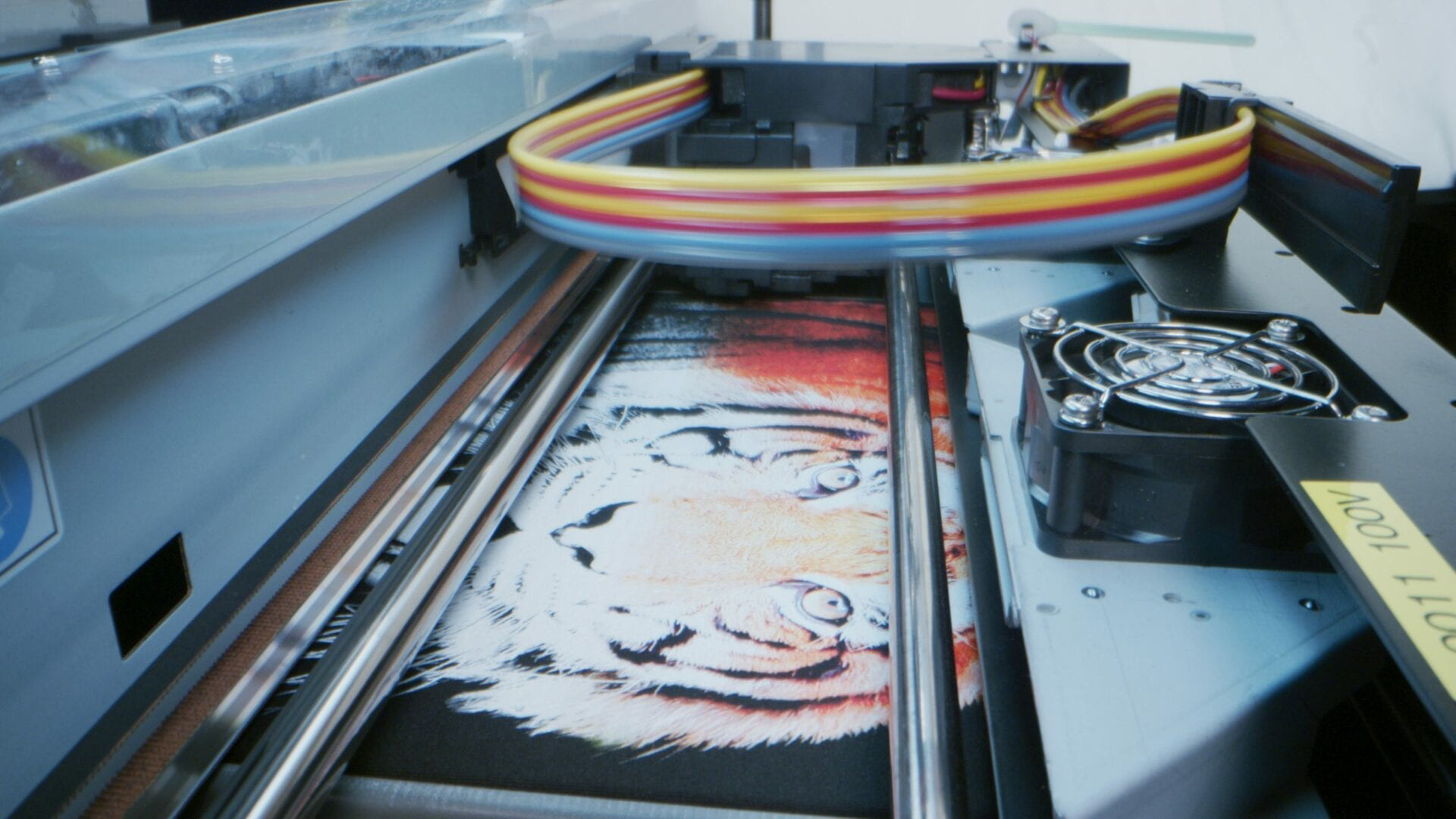

Direct-To-Garment (also known as DTG) printing is almost exactly how it sounds. DTG printing is a process of printing directly on textiles and other items using inkjet technology. It really is as cool as it sounds.

A DTG Printer is similar to how your home office printer works. Except, instead of using paper, in a DTG printer it’s textiles like shirts, face masks, hoodies, shoes, etc. The printers have a flat surface, called a platen, that you lay your garment down onto. Once the print button has been pressed, this platen will go into the printer and start the print process. Once it’s done printing, the platen will come back out for you to see the printed product.

DTG was first introduced in the United States in 1996 and is a very young segment in the textile industry compared to other printing methods. In 2019, DTG was valued at over $2.5 billion with a compound annual growth rate of 10.5% through 2021. By 2024, this segment will grow to 40%, making DTG the fastest growing segment in the textile industry. With the amazing technology that is built in the RICOH Ri 2000, not only will you get amazing vibrant prints, but you will be able to print quicker too. In many cases, it is twice as fast compared to other printers.

To find out more about how Millcraft’s DTG Solutions can help you get into the game of DTG printing, reach out to one of our DTG Specialists.

Continue Reading

Around the Collar topic: Garment Selection

Garment selection is one of the most important aspects of achieving retail-level prints with your DTG printer. In this article we will discuss the various types of fabrics used and what to look for when adding blank garments to your catalog… Ring-Spun & Combed...

History of Direct to Garment

The advancements in Direct to Garment printers, since its introduction, have been simply amazing. Back in the 1990’s, Matthew Rhome had an idea of being able to use an ink jet printer to print directly onto a t-shirt. By 1996, he filed a patent for Direct to Garment...