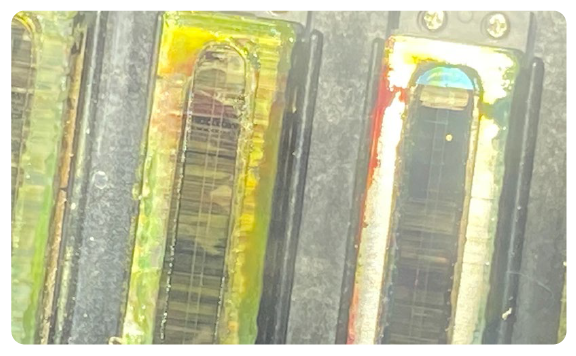

Proper print head maintenance can be the difference between your DTG printer making you money or costing you money. White ink tends to build up and coagulate at a rapid pace, especially when the environment is hot and/or dry. This dried ink around the nozzle plate can lead to clogging and eventually a failure of the print head, causing lost revenue while waiting for replacement parts.

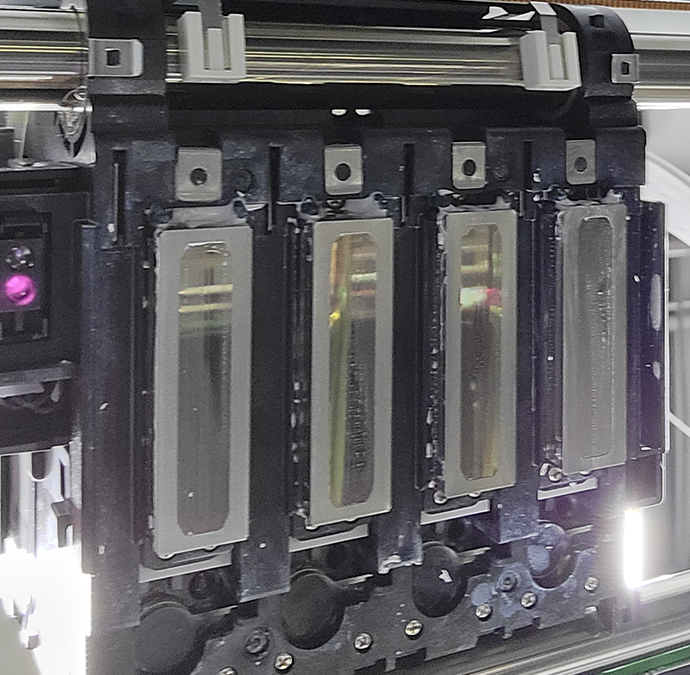

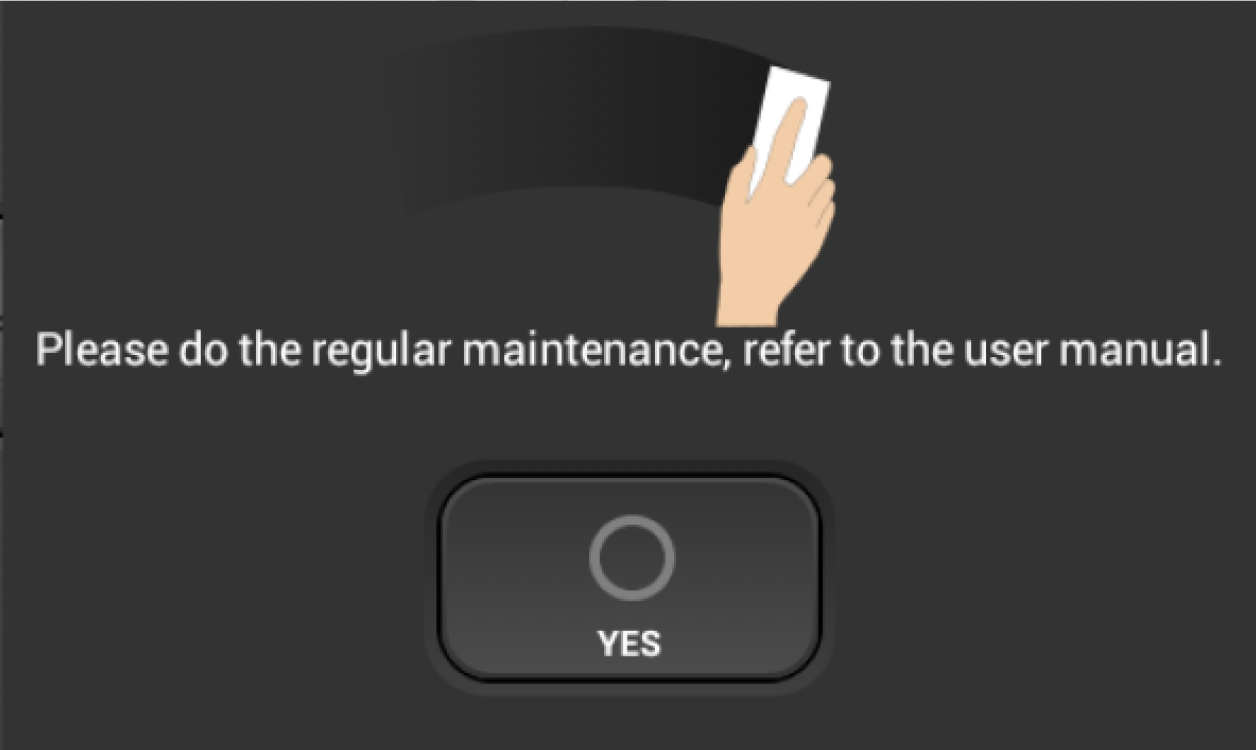

The RICOH Ri 1000/Ri 2000 DTG printers follow a built-in maintenance schedule and display a notification on the LCD screen, so the operator knows when it is time for components to be cleaned.

As great of a system, as it is, there are still situations where we have found additional preventative maintenance is required to keep the printer producing the award-winning prints they are known for. In many cases, you will start to see your opacity doesn’t pop, banding appears, and your nozzle checks will look bad. These are all indicators that the printer needs a physical cleaning. It could be as simple as debris on the wiper blade or a build-up of excess ink on the bottom of the print head. Regardless, don’t wait till the printer notifies you that it’s time for a cleaning, stop printing and start cleaning. Spending a few minutes going over the maintenance station and print head with a foam swab is much better than ruining print jobs.

On the Ri 2000 a Jig Cleaning will be requested by the printer. This does a really good job at cleaning the print head, but a dry foam swab should be used to wipe between the nozzle plates a minimum of once per month. The printer will ask the operator to verify everything looks good before it completes the Jig Cleaning. During this time, a foam swab should be used to remove any excess ink left behind. The more you use the printer the faster the ink can build up, and the harder it is for the Jig to remove all the dried ink. White ink becomes very rubbery and sticky making it difficult to remove as it builds up. Staying on top of the maintenance, and visually inspecting the print head, is required even with the Ri 2000’s Jig.

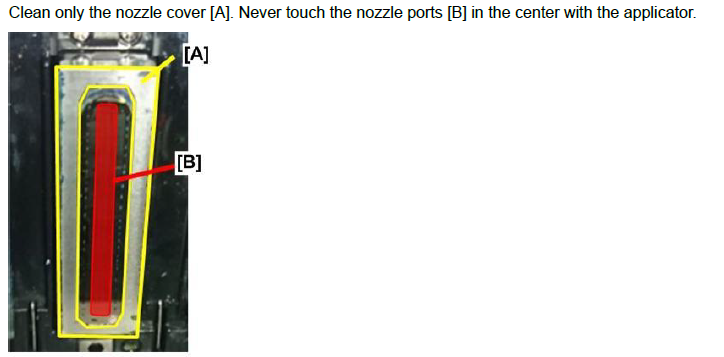

The Ri 1000 doesn’t utilize a cleaning Jig like the Ri 2000, so users are required to use a dry foam swab to remove excess ink on the bottom of the print head. In extreme cases, the foam swab isn’t able to remove the dried ink and will require a more physical approach. If needed (unplug the printer while doing this) use a lint-free cloth, place it over your fingernail, and lightly scrape the outer edges of the print head to remove the dried ink. At this point, you will likely be removing chunks of stringy dried ink. This should be taken as a reminder of why we need to stay on top of the maintenance.

*ALWAYS BE CAUTIOUS AROUND THE NOZZLE PLATE

*DAMAGE TO THE PRINT HEAD CAN OCCUR IF USING A WET FOAM SWAB

Millcraft’s DTG Solutions is here to help you excel in the Direct to Garment market. If you need any further assistance with print head maintenance or anything else, please fill out a ticket to contact us.